3D Printing could Change the Car Industry as we know it

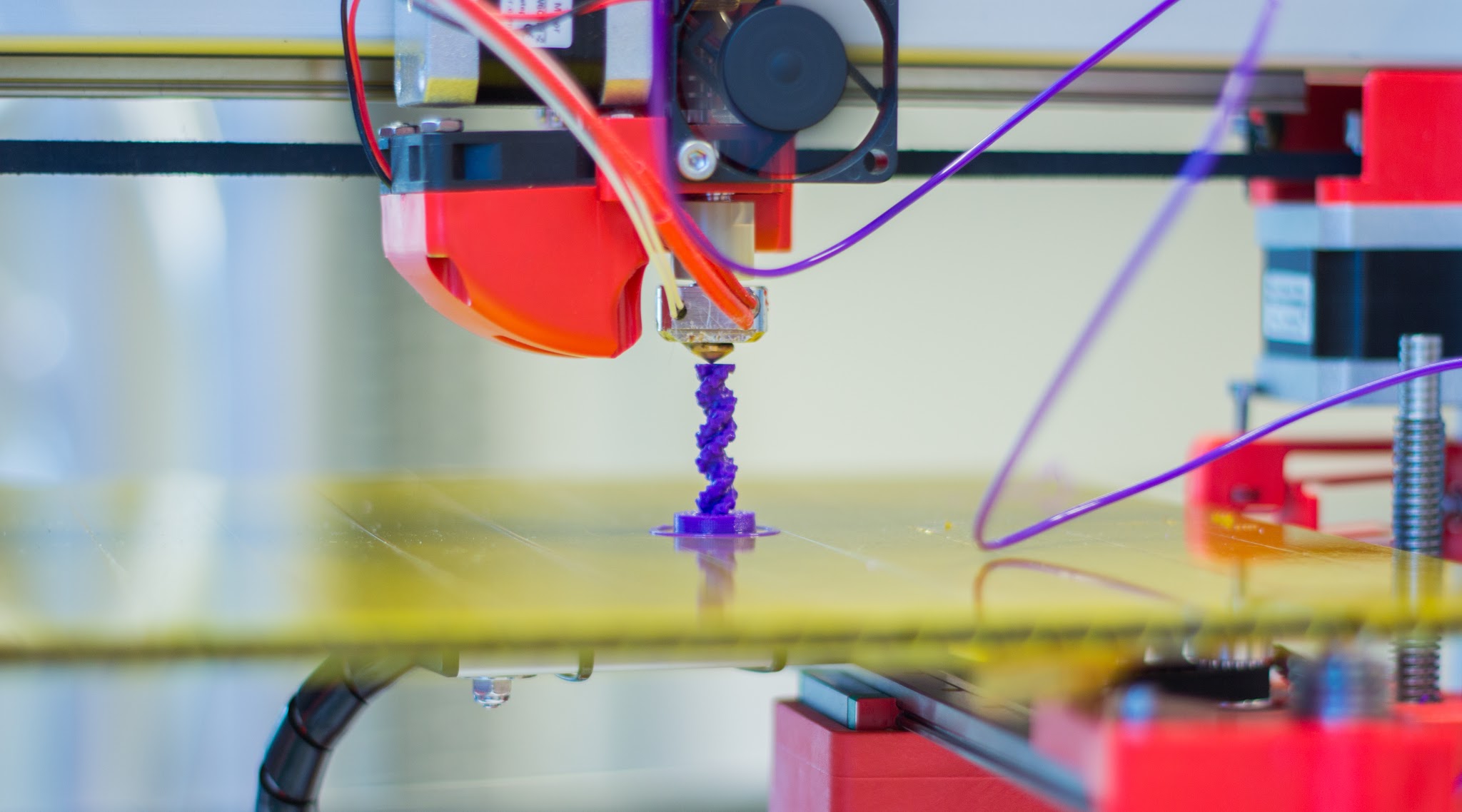

As we all know it, paper is not the only printer friendly material in the 21st Century and owing to modern technology, it is time to move beyond the rather limited world offered by the two dimensions. Take for example the plastic gun created by a 3D printer, which was built, fired and claimed to be undetectable by traditional scanning machines. Can this technology be applied to cars?

You might have cringed at the sight of the Aston Martin DB5 in the James Bond movie Skyfall being filled with bullets. But you may have been a little more at ease if you knew that that wasn’t a traditional scale model, but in fact a 3D printed model.

Want a real car, one that you can get into and drive? Could that be printed too? Well sure it could! This is what was showcased by printed car pioneers Local Motors at the recent Detroit Motor show, where they actually printed a car at their kiosk in an attempt to drive it away by the end of the show. To prove that they were serious, they displayed what they created there and then at the show for all the spectators to see.

The theory behind the 3D printed car is so mind blowing, at least it is when you first think about it, that it forces you to put to one side the more challenging issues facing those who’d wished they would realise into a commercial reality. Local Motors chief marketing officer Elle Shelley claims that it’s all about the tooling and there are just 47 parts that make up the vehicle, which they call the Strati. This could potentially cause some headaches for car traders and dealers trying to insure cars such as this in the future with commercial insurance .

If this dream by Local Motors does come true, the world will be filled with small factories, which would all be printing vehicles that are not only crowd designed but also crowd funded. People enter local competitions, where the winning design is printed. Shelley states that you don’t need to make a profit on a million cars, because you’ll make it on a 1000 cars. Adding to this, it may take five years for a conventional car manufacturer to design a new car but the Strati went from production to a drivable state in just five months, with of course some help from the running gear and powertrain of a Renault Twizy.

It then takes approximately 44 hours to print using carbon reinforced plastic, and a couple of hours to soften the resulting rough surfaces, and then a day to put all the panels in place. Unlike normal car owners who are forced to either keep or sell their vehicle, you can simply take the vehicle back to the factory to have it melted down and turned into a new design. Local Motors says that the Strati is not actually a production car, but something similar complete with appropriate weather equipment will be in production by the end of this year and will cost between $18,000 and $30,000 in North America.

We wonder what the car insurance costs would be on a 3D printed car, would it be strictly speaking modified car insurance at this stage?

Local Motors understands that if they find it tough to pave the way for its printed cars in the United States, there are several other countries where they would be welcomed.